1. BeCu의 여러 이름들:

- Copper Beryllium, Beryllium Bronze, Alloy 172, spring Copper

- Be에 대해서: https://www.thoughtco.com/metal-profile-beryllium-2340127

2. BeCu의 장점들

• Conductive, Ductile, Stampable, Corrosion resistant, Easily Formed, Non-sparking, Non-magnetic

2-1 Strength

BeCu는 크게 두 가지 클래스로 나눌 수 있다; High strength BeCu* (C17200 and C17300) 그리고 High conductivity BeCu** (C17500 C17510).

• For a high-strength BeCu, its strength can exceed about 200,000 psi while maintaining good electrical and thermal conductivity. Compared to BeCu, other types of Copper alloys have much softer.

• BeCu maintains good strength at even low temperatures. Because of it, BeCu is widely used in cryogenics.

• due to its high endurance strength, it is suitable for heavy cyclic load applications

* High strength BeCu: The most commonly used BeCu containing 1.8-2% beryllium and showing the below properties

(1) Tensile strength range: 60-220 ksi (kilopounds per square inch)

(2) Fatigue strength: 30-50 ksi per 10^8 cycles

(3) C17200: Due to its highest hardness among BeCu families with good electric and thermal conductivities, it is widly used in applications.

2-2 Electrical and thermal conductivity

• With non-sparking, it has good electrical and thermal conductivity, leading it to be used for electronic connectors, computer components, etc.

• Thermal conductivity of BeCu is between steel and aluminum.

- 62 Btu/ff-deg: 3-5 times higher than tool seel

2-3 Non-magnetic

Because of its non-magnetism, BeCu tools and components can operate unaffected within magnetic fields.

2-4 Hardness

One of the most important properties of BeCu. Even though BeCu can be softened or hardened depending on different heat treatment processes, its hardness, after heat treatment, can be close to high-grade alloy steels while keeping the advantages of BeCu.

2-5 High resistance to Corrosion and Oxidation

Extremely high resistance against corrosion. Because of it, Alloy 172 is commonly used for tools that require high corrosion resistance, such as wire, electronic springs, gas equipment components, as well as undersea and marine telecom components. Even BeCu has higher resistance to corrosion and oxidation than steel

2-6 High ductility and excellent formability for forming, machining, and metalworking process

3. Application of BeCu

BeCu can be applied to various fields, including oilfield tools, aerospace landing gears, robotic welding, etc.

- Computers and electronics

- Fabrications of non-sparking tools

- Fasteners

- Telecommunication products

- Valve Seats and Cryogenics

- Injection mold design

- Musical Instruments

3-1 Non-sparking tools Because of their non-sparking characteristic, BeCu can be used in oil platforms and coal mines where any sparking leads to dangerous situations. Thus, tools such as wrenches, screwdrivers, and hammers used in the above environments commonly comprise BeCu.

3-2 Cryogenics Because it retains good electric and thermal conductivities and strength at various extreme temperature ranges, BeCu can be used in cryogenics.

4. Safety issue on BeCu [4]

Toxicology: BeCu in a solid state doesn't have a health concern. However, when it becomes powders or vapors that can be inhaled during machining or welding, it can cause serious health problems, called chronic beryllium diseases. Thus, another copper alloy would be used instead of it as an alternative.

Inhalation: could cause serious lung damage due to chronic beryllium diseases that prevent to exchange of oxygen between the lungs and the bloodstream.

NOTE: Beryllium is listed as a carcinogen by the National Toxicology Program (NTP)

BeCu에 대한 물리적 특성 정리

[1] https://www.meadmetals.com/metal-products/beryllium-copper

Reference

[1] https://www.meadmetals.com/blog/5-unique-properties-of-beryllium-copper

[2] https://www.meadmetals.com/blog/common-uses-for-beryllium-copper

[3] https://www.sequoia-brass-copper.com/blog/beryllium-copper-properties/

[4] https://www.chemistrylearner.com/beryllium-copper.html

[5] https://www.corrosionpedia.com/beryllium-copper-alloys-vs-steel-which-metal-works-harder/2/6816

[6] https://en.wikipedia.org/wiki/Beryllium_copper

'과학 (Science) > 실험과 관련된 것들' 카테고리의 다른 글

| [화학물질] 톨루엔 (Toluen), 벤진 (Benzene), (0) | 2024.11.09 |

|---|---|

| [실험] 화학 기구들 영어이름 (0) | 2024.08.14 |

| [실험] The BET method/Theory (0) | 2024.01.03 |

| [Materials] GE varnish (0) | 2023.07.07 |

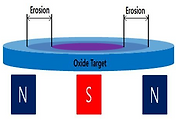

| [Physical Vapor Deposition] Sputter Depositions (0) | 2023.06.24 |

댓글